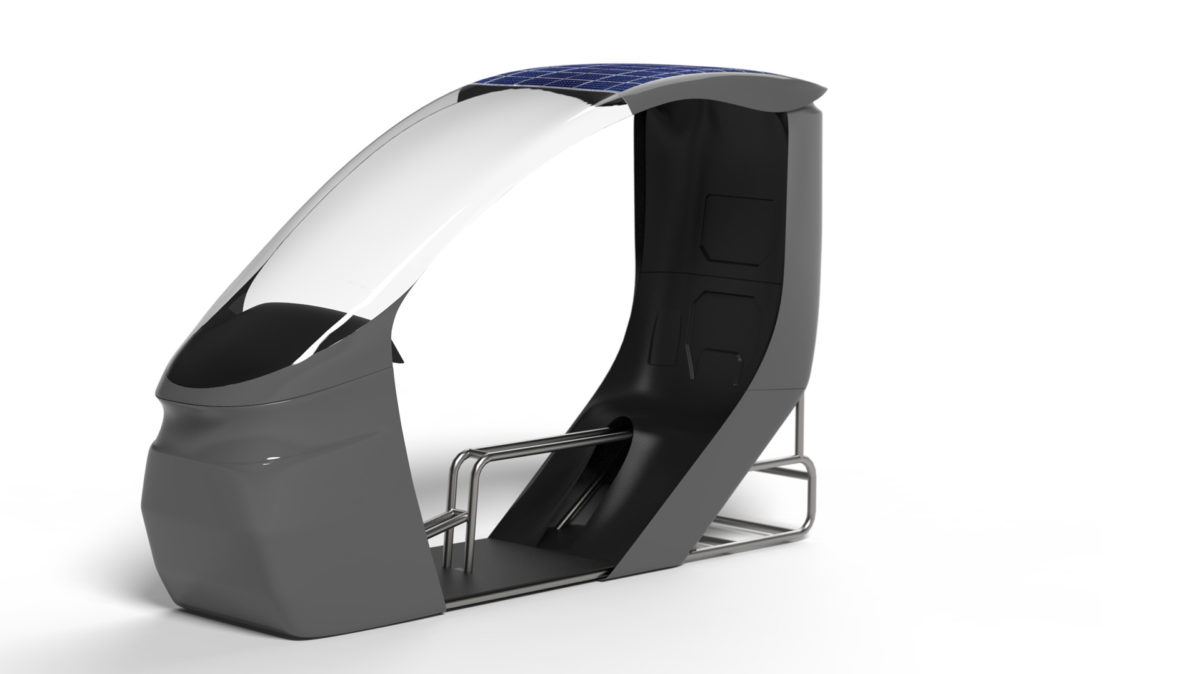

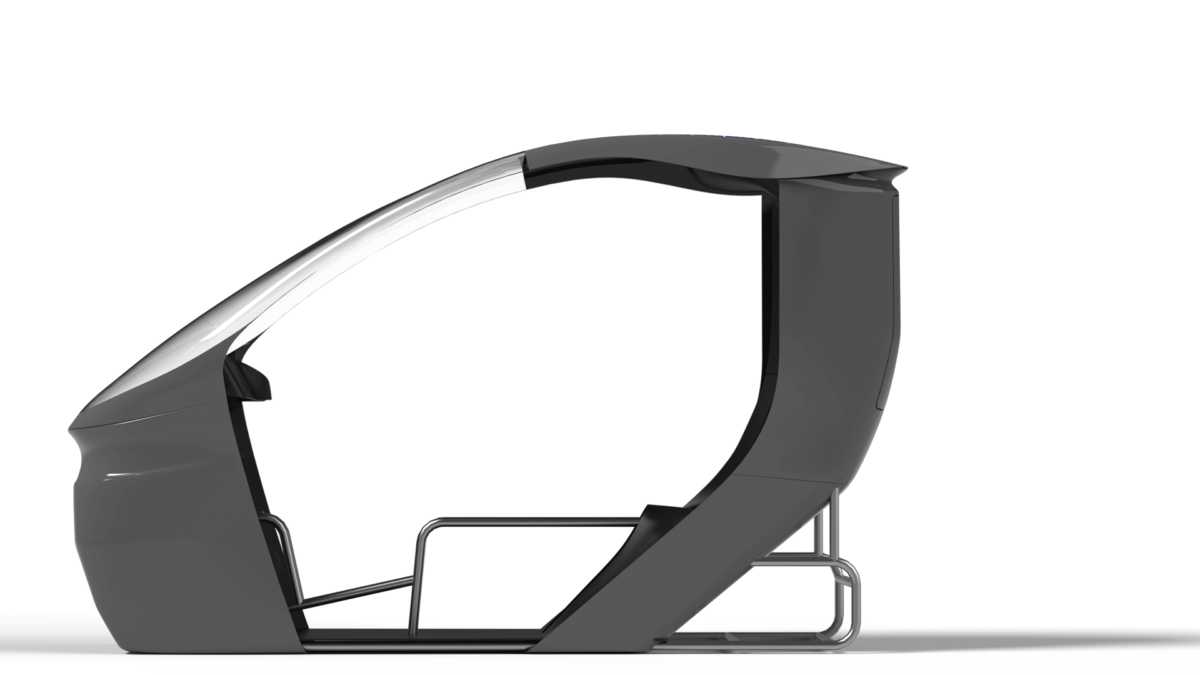

CityQ

Role

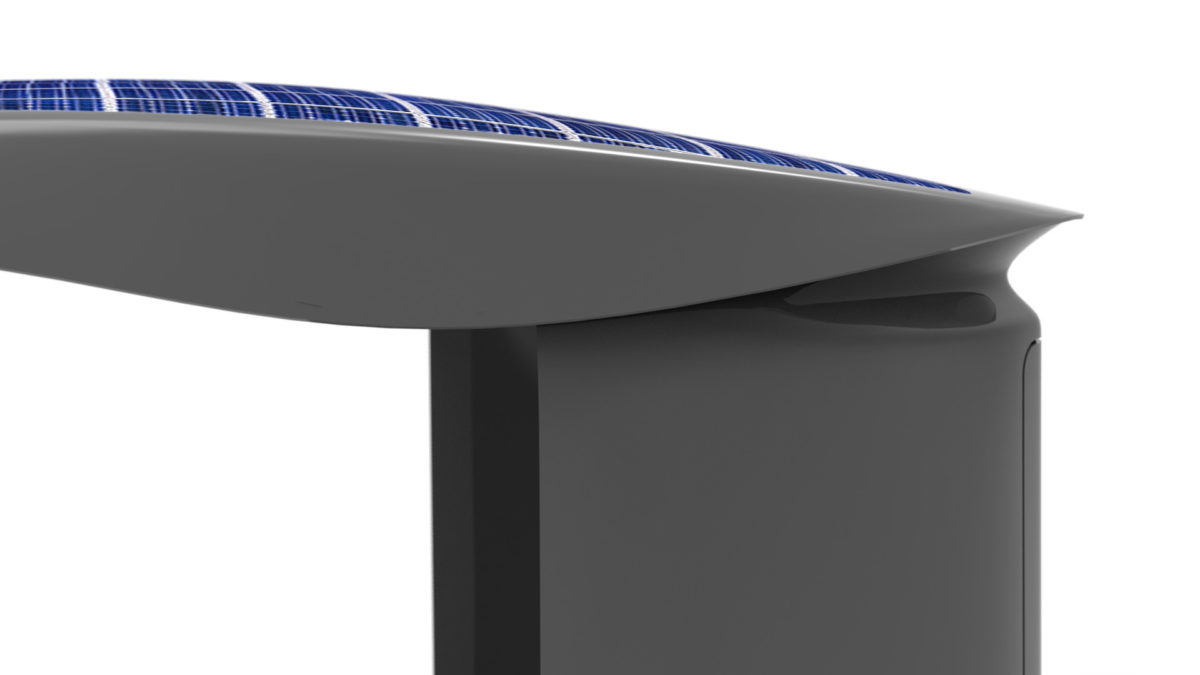

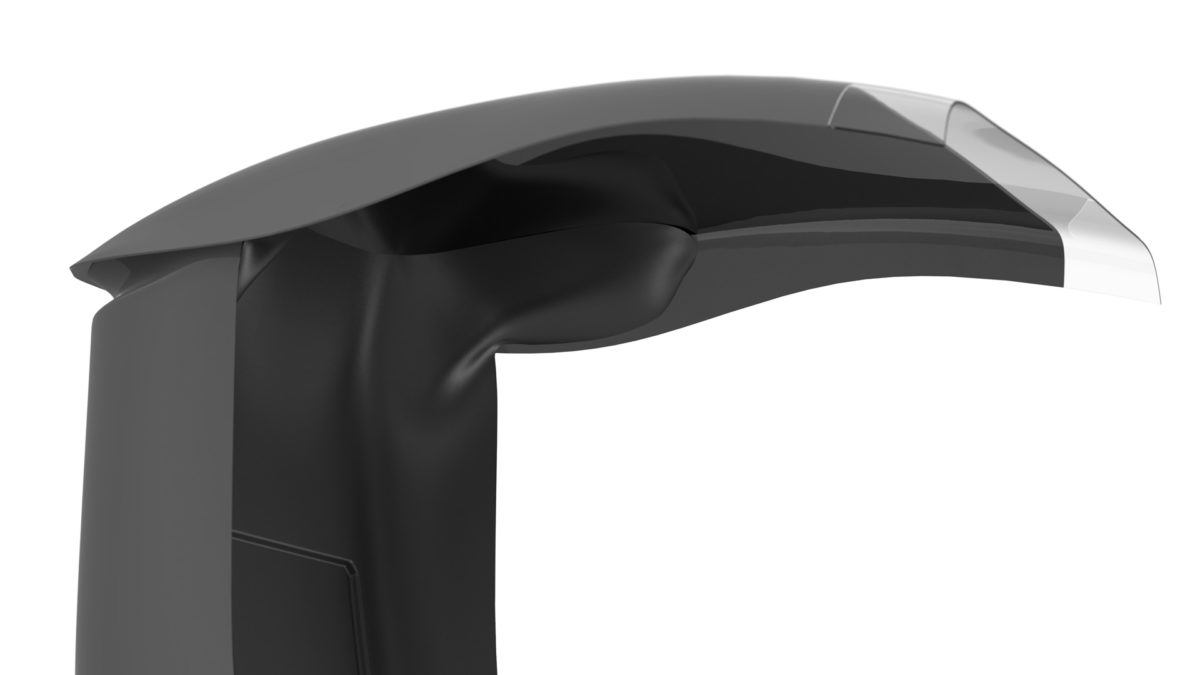

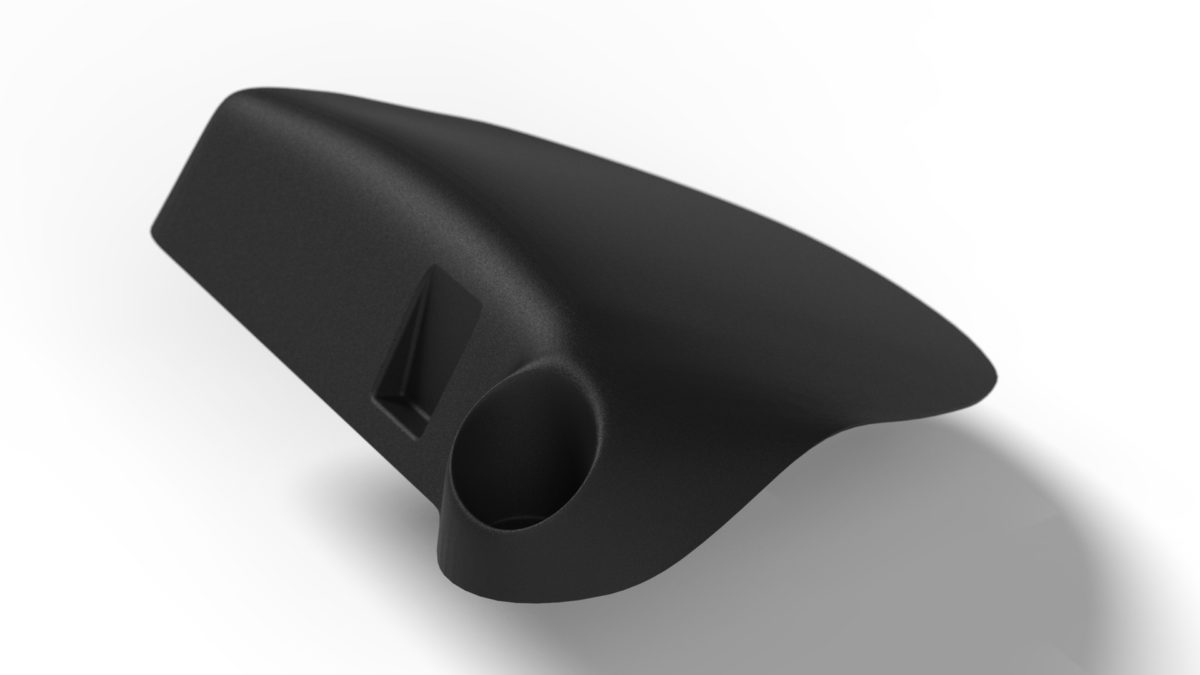

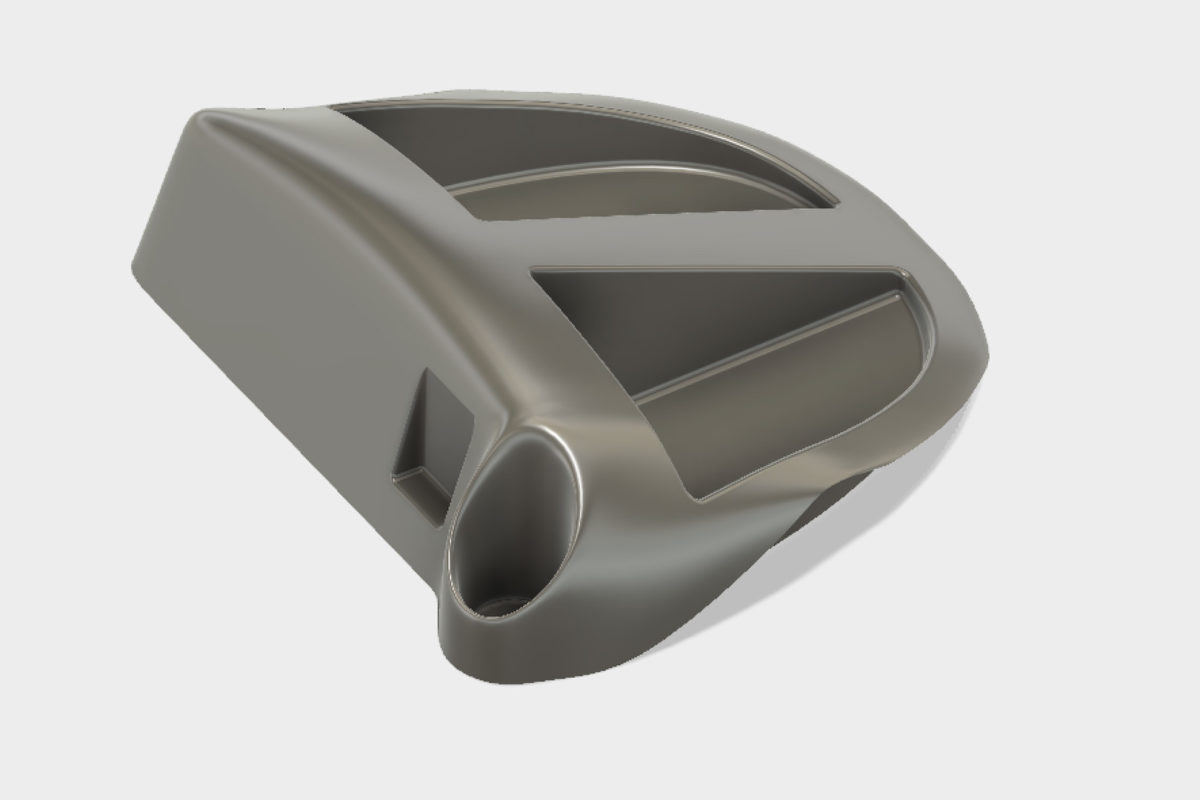

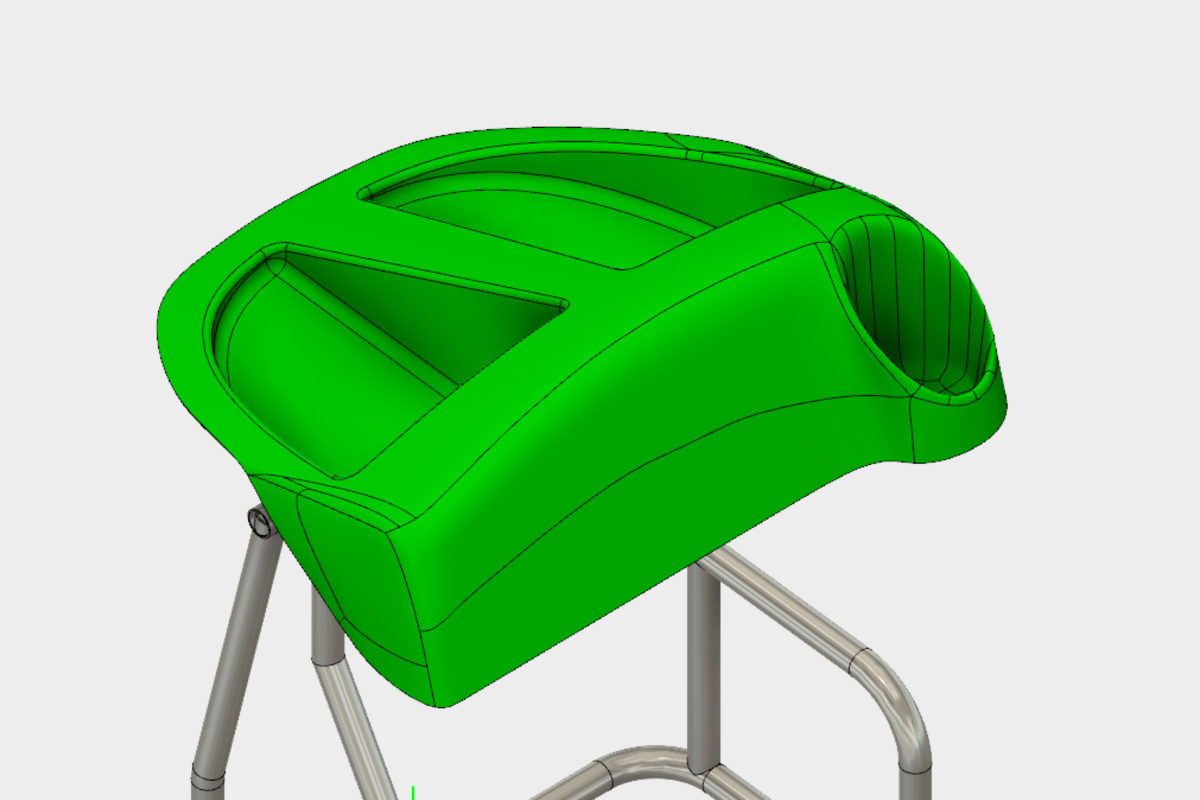

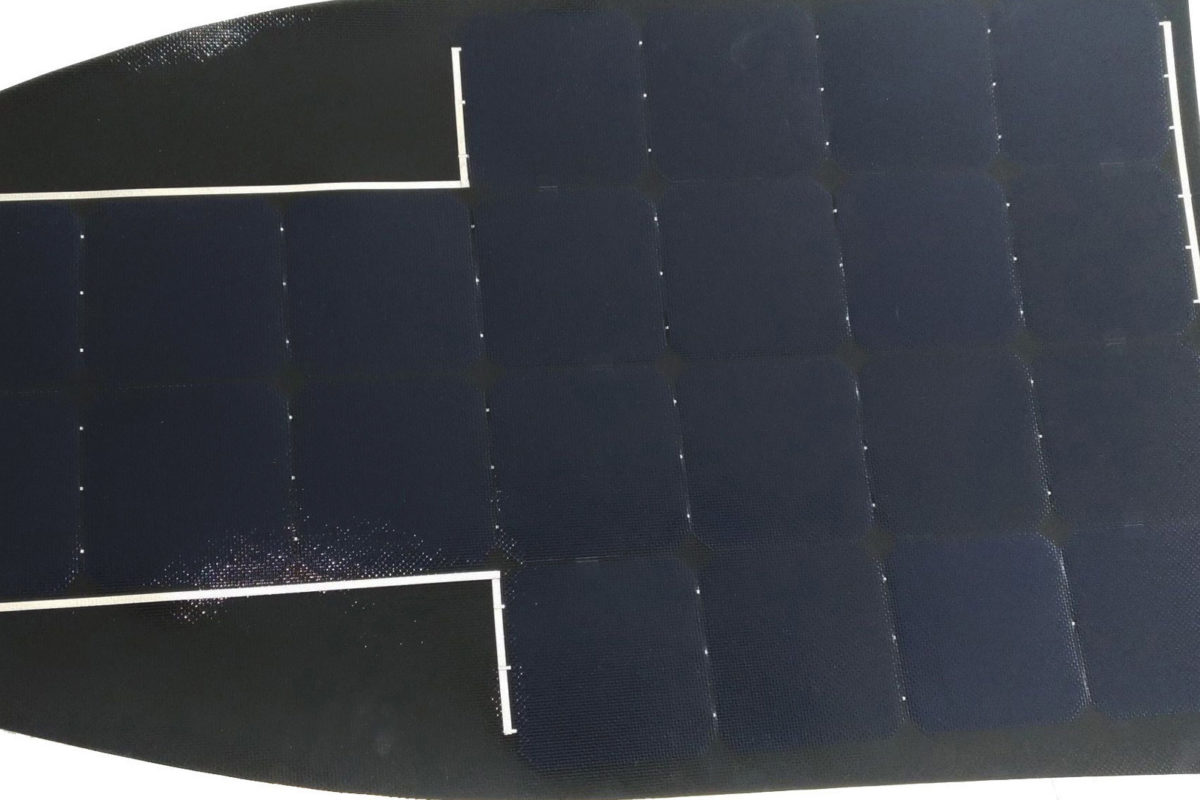

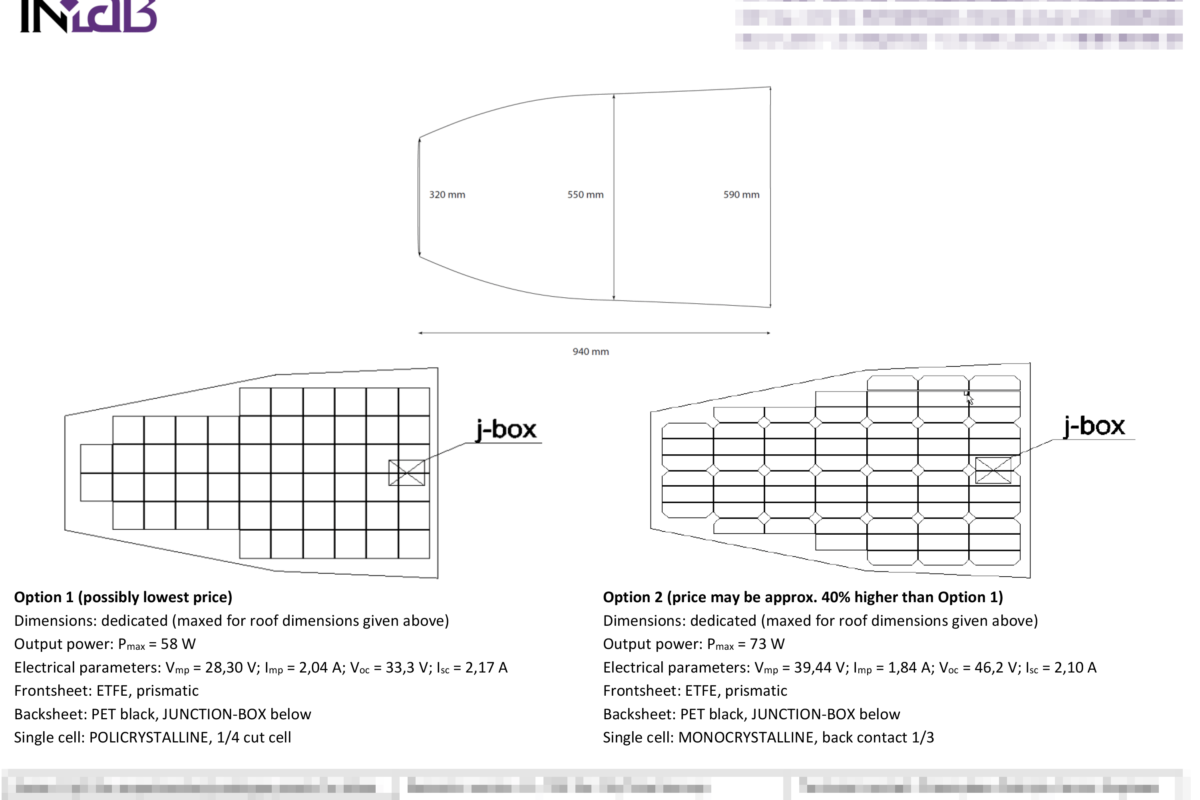

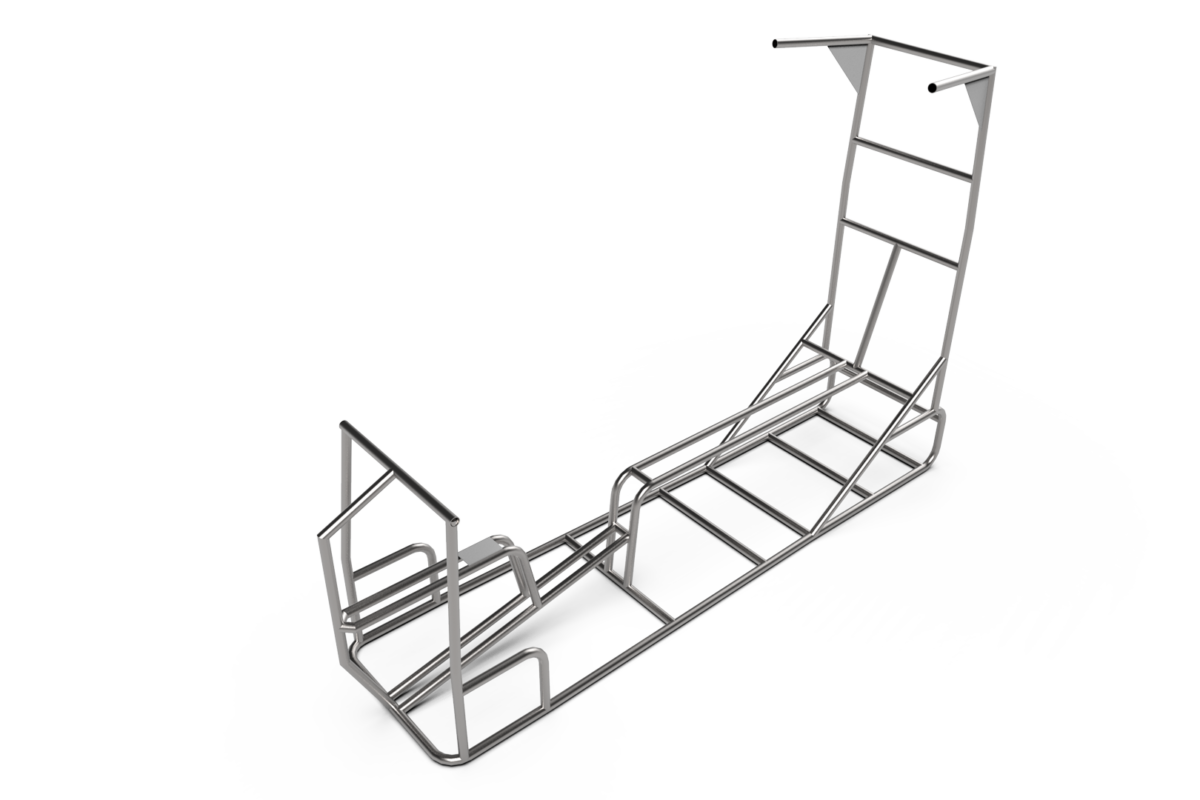

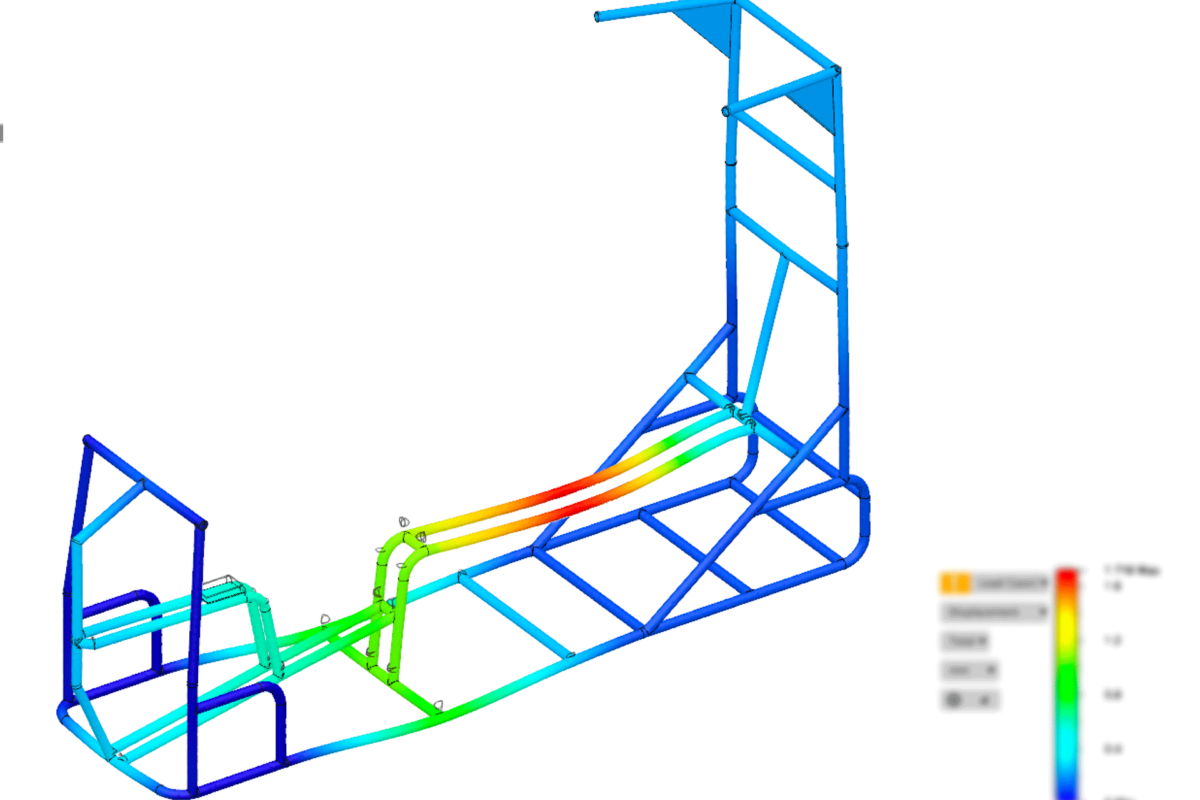

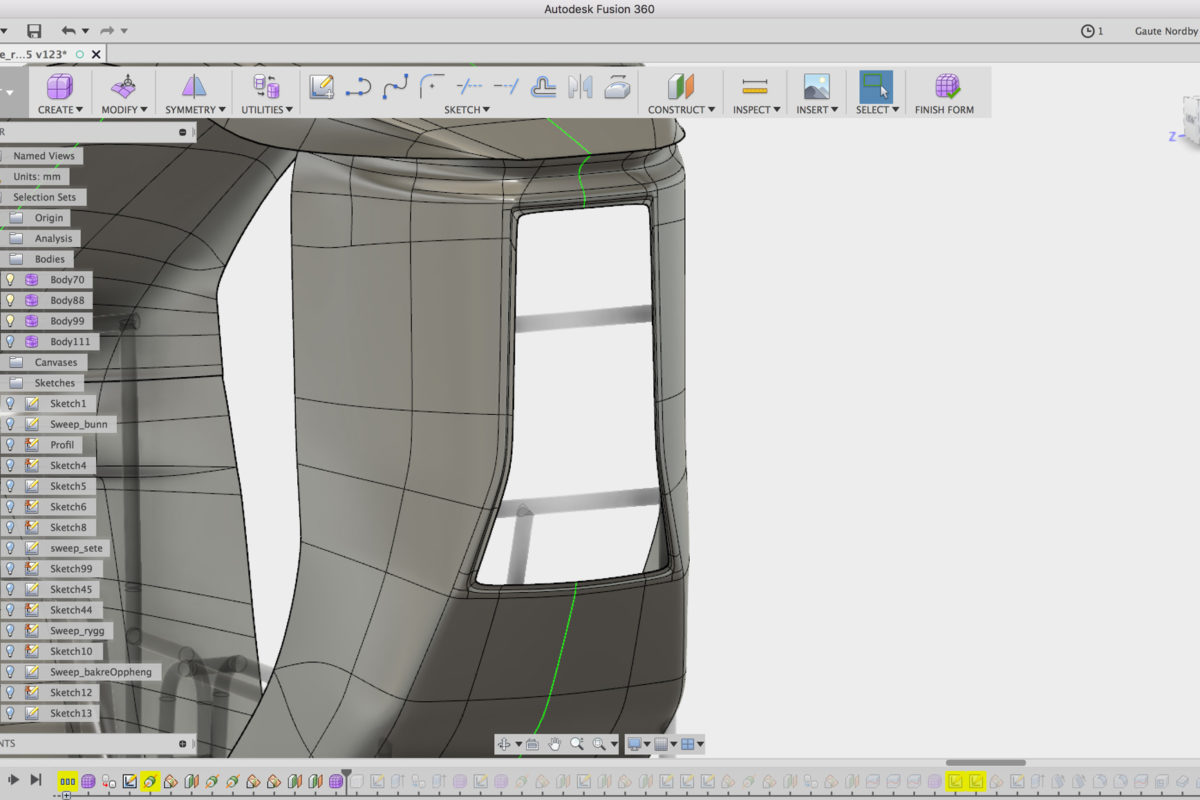

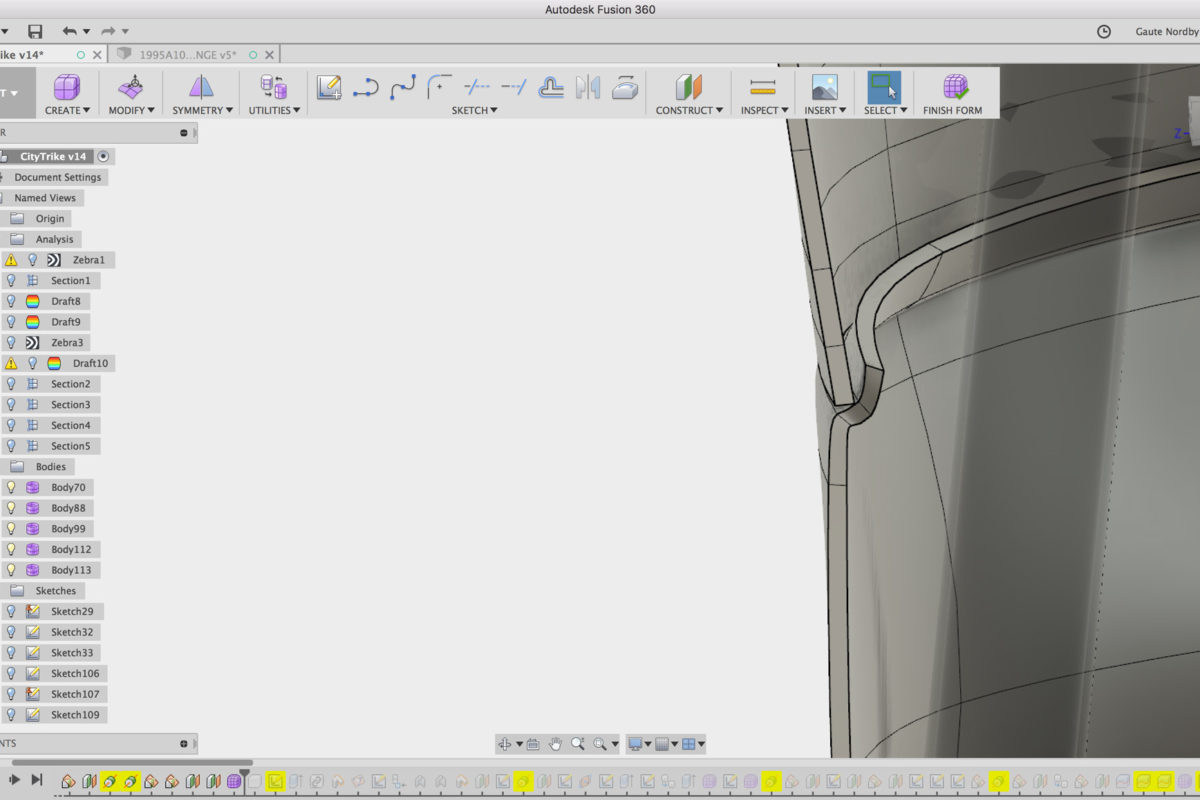

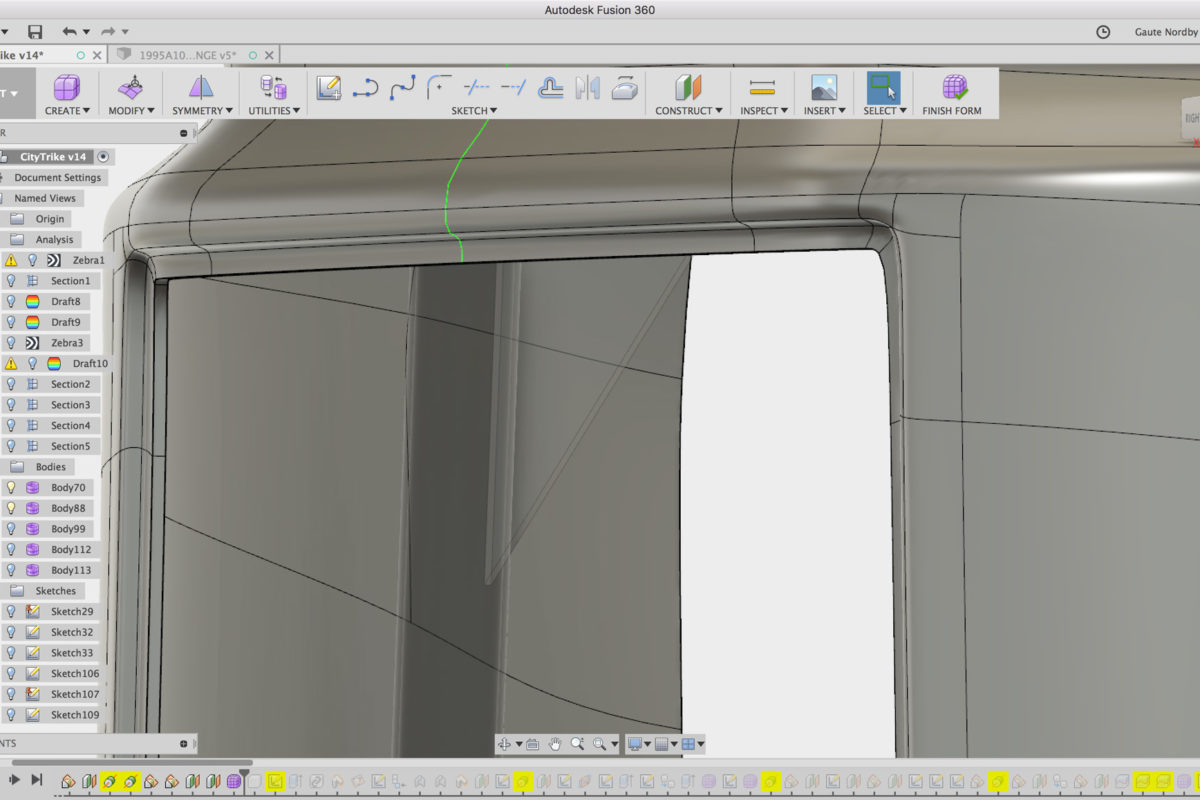

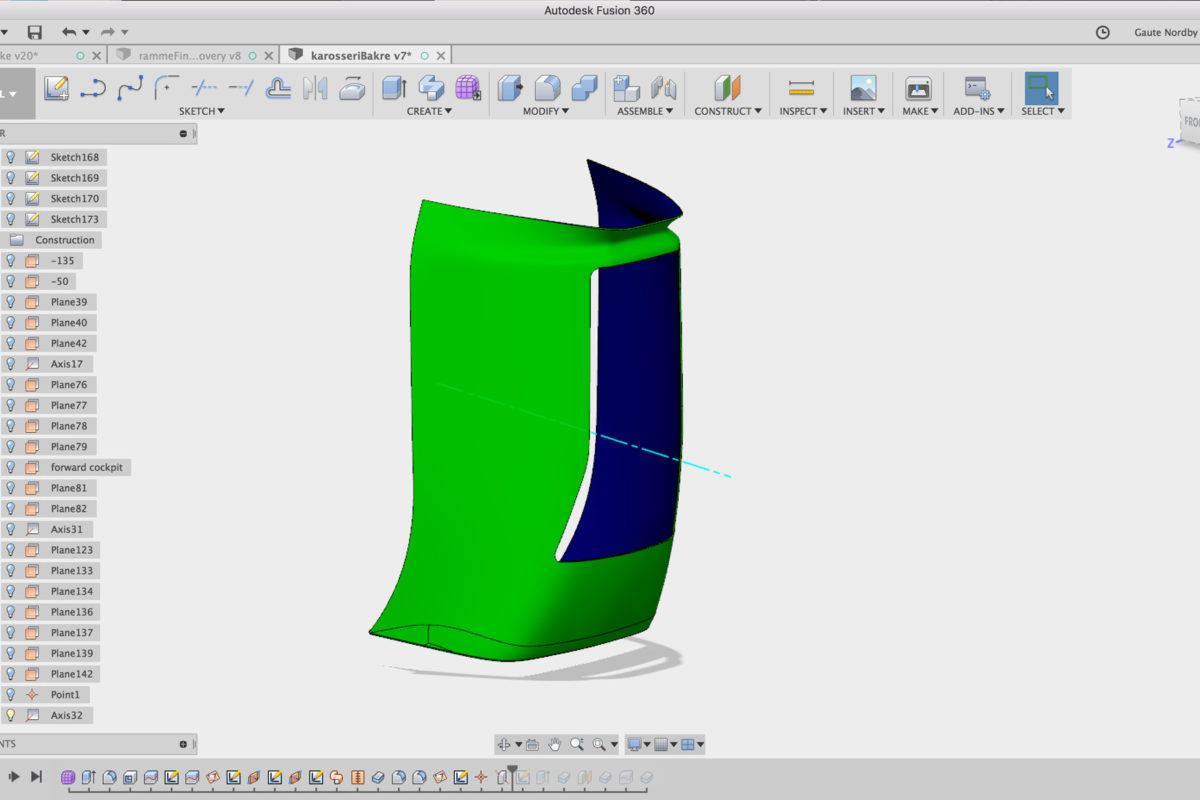

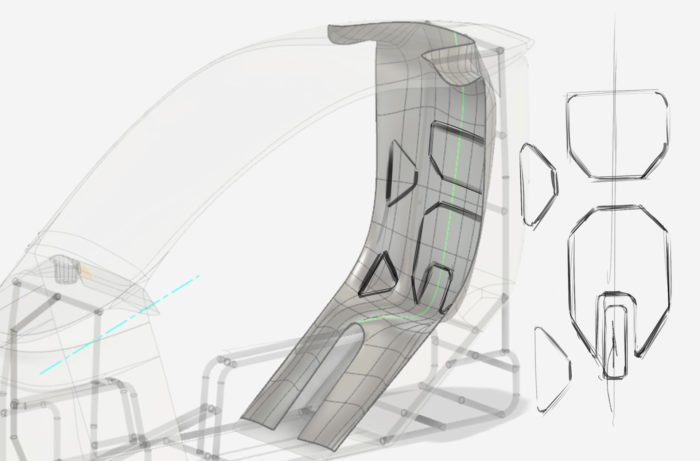

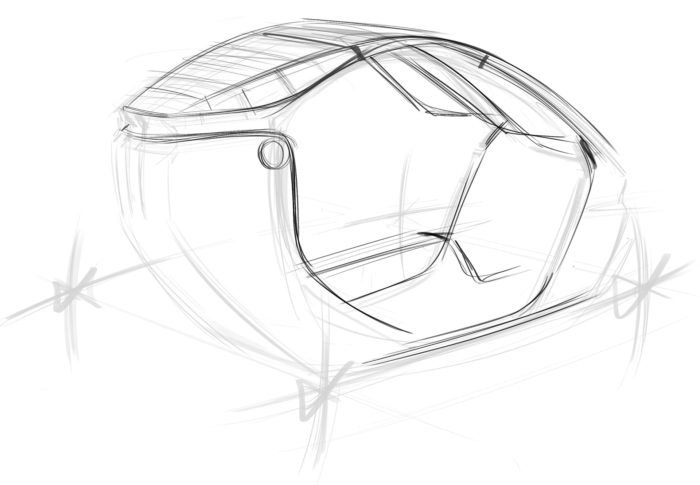

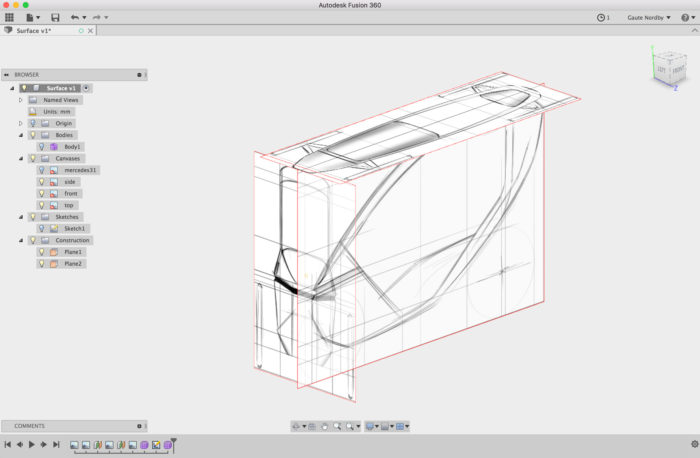

Designed body, chassis, and solar panel

Team

Nikolai Hiorth, Nima Shahinian

Timeline

22. May – 18. August 2017 (3 Months)

Light Electric Vehicle

City drivers are increasingly turning to “micro-mobility” options for their daily commute. CityQ merges the advantages of cycling with better user accessibility and all-weather protection, thus relieving road congestion and reducing greenhouse gas emissions from motor vehicles. In inner cities where car traffic is restricted, there is an increasing need for such new vehicles.

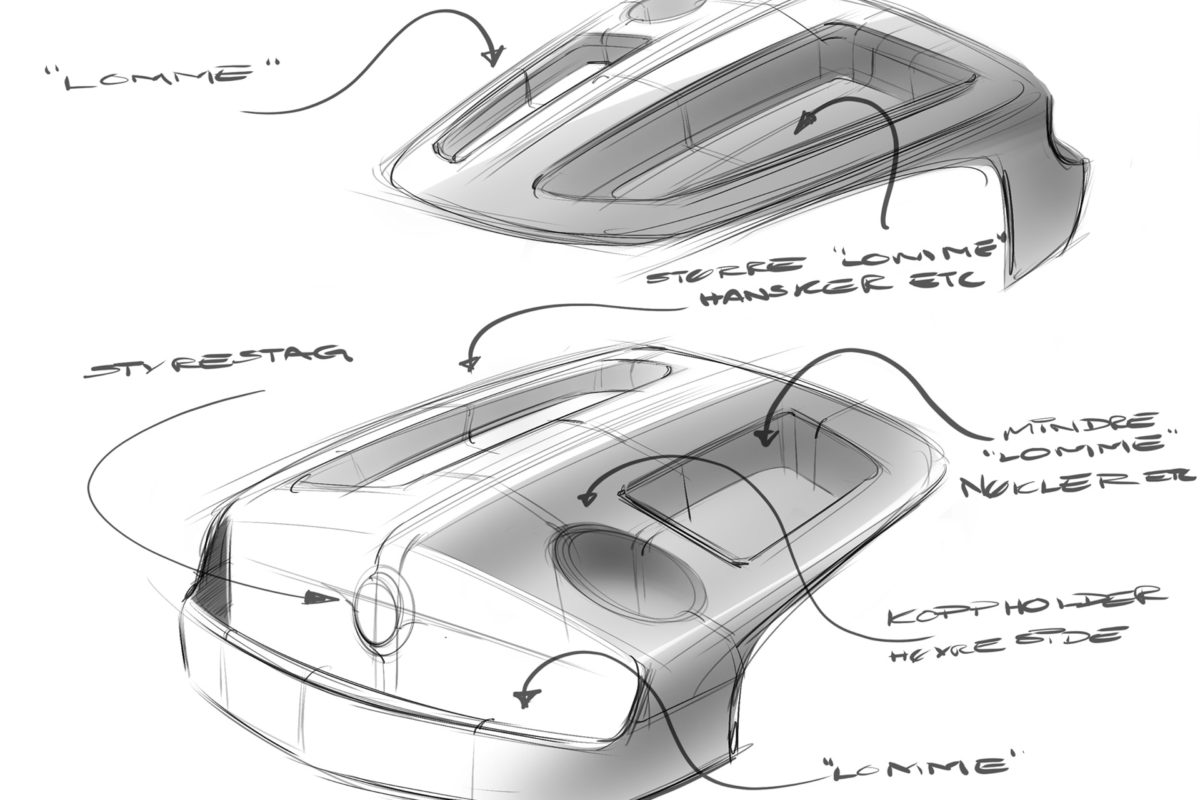

During my internship at the product development firm HOOS, Oslo Norway, our client requested a prototype for a new concept. The team consisted of Nima as project manager and industrial designer, Nikolai as mechanical engineer and myself as a product engineer. *All drawings shown are done by Nima.