Sustainable Beverages

Wim replaces single-use bottles with a circular beverage distribution system so that people are able to continue enjoying beverages, but without the waste. Instead of producing beverages far away and hauling heavy commodities to product shelves, we do it all at the point of retail with our glass bottles and station. The bottle is filled on-demand and labels applied as soon as the customer selects their beverage of choice. Once finished, the customer can bring back the bottle to any stations in our network where it will be cleaned and prepared for the cycle to repeat.

We’ve set out to create a better experience than the incumbent model. The cyclical nature of Wim not only reduces the carbon footprint by up to 75%, but it also allows us to offer an unlimited beverage membership for a monthly fee. To make it even easier, the bottle is embedded with a NFC tag turning the bottle itself into a payment token for members–no need to bring cash or credit cards. The unrivaled product value combined with ease of use makes Wim the first sustainable alternative to truly compete against disposable packaging.

DEVELOPMENT

Development Strategy

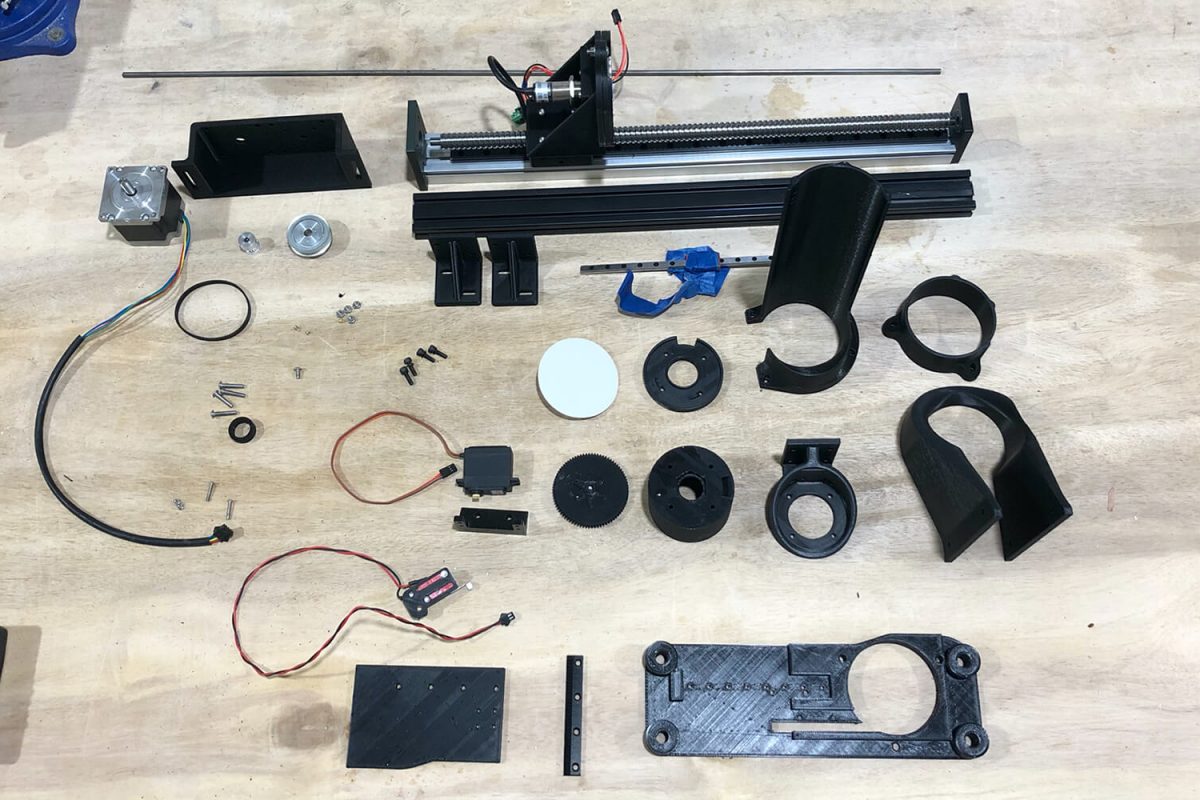

We had a lot to accomplish is a short amount of time. As the CTO, I led our multi-disciplinary internal and external team through 3 prototypes, our bottle design, a beverage production line, QA test jigs, and manufacturing partnerships. Our latest prototype was designed and launched in under 6 months, with just my cofounder and I working on the hardware. To accomplish this, we incorporated an iterative design approach through-out. Here showing the progression of filling assembly, from filling with a hose to automatic filling with selective dosing of macro, micro and base.

Prototyping

We started out testing out biggest assumptions and concerns. The first challenge was to see if people were willing to drink from reusable containers. After a short pilot, we could easily conclude that if designed correctly, reuse was not a concern for customers. The second challenge was to understand if we could fit everything we need into an attractive package that our location partners would accept.

1st prototype was a fridge on-top of a custom drop-off unit

2nd prototype gave us a rudimentary understanding of tech and size

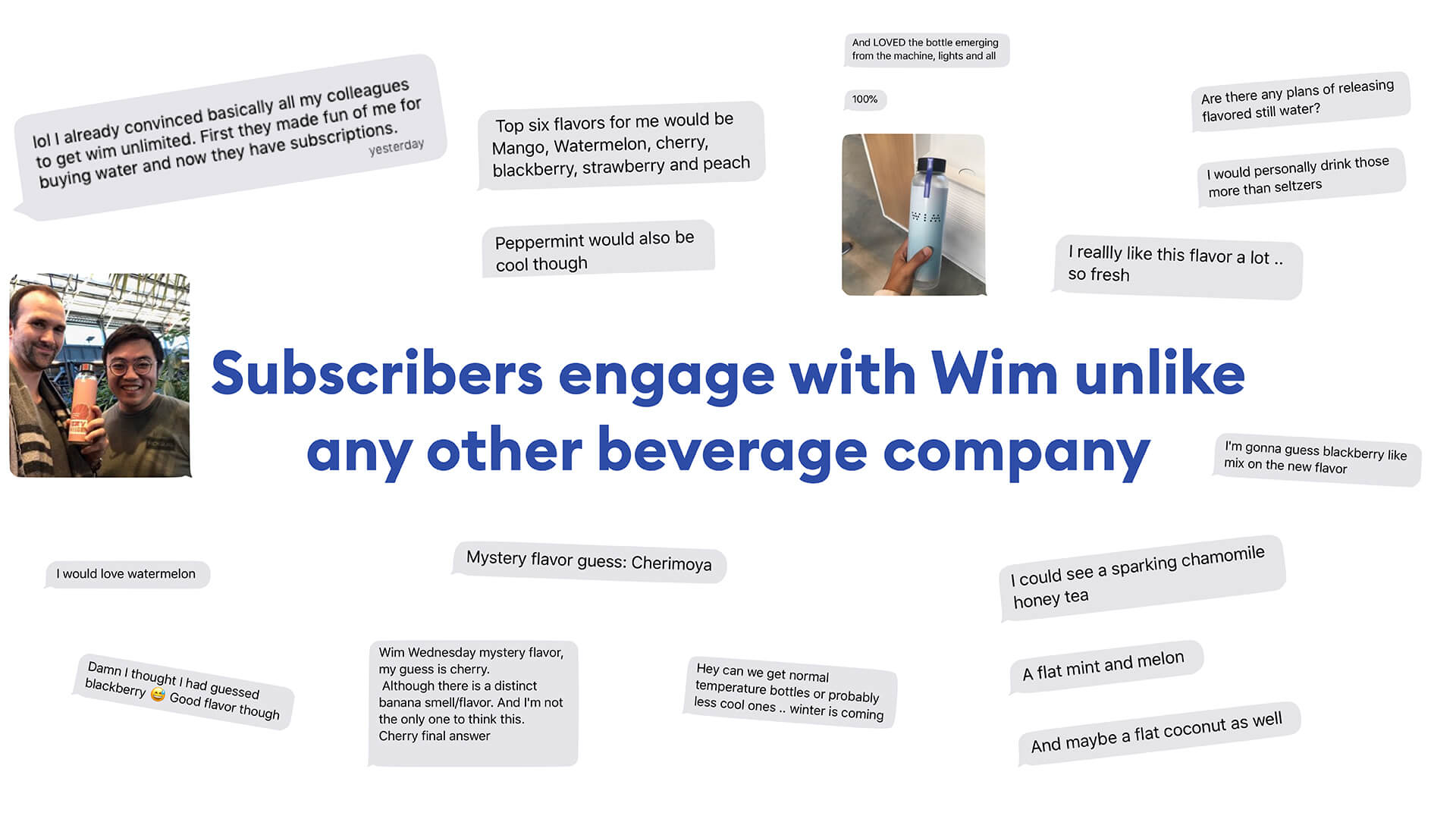

CUSTOMER FEEDBACK